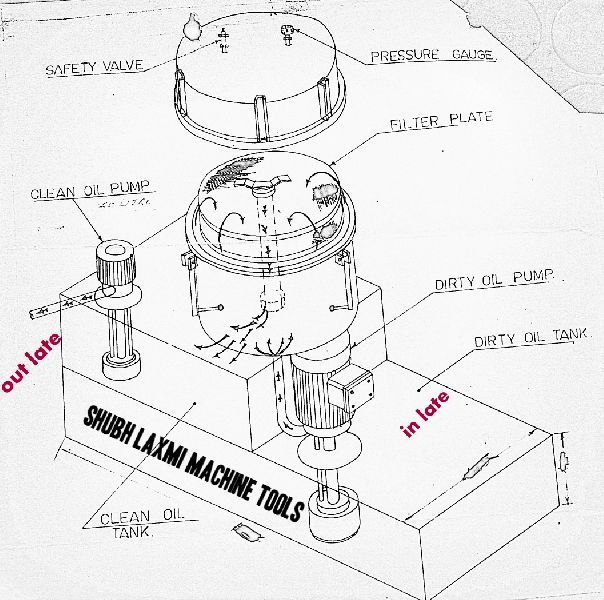

Industrial Oil Filtration System

Leading Manufacturers, Exporters, Wholesaler, Retailer and Trader of CNC TRAMP OIL SAPARATOR, FRYER OIL FILTER MACINE, Honing Oil Filter Machine, Lube Oil Filters, OIL SKIMMER MINI and TRAMP OIL SEPARATOR from Surendranagar.

| Business Type | Manufacturer |

| Finishing | Polished |

| Condition | New |

| Operating Type | Automatic |

| Certification | ISO 9001:2008 Certified |

| Packaging Type | Wooden Box |

| Warranty | 1 Year |

| Country of Origin | India,India |

| Type | CNC TRAMP OIL |

| Brand Name | Shubhlaxmi Machine Tools |

| Port | Sanand |

| Payment Terms | L/C, D/A |

| Delivery Time | 2-3 Weeks |

Preferred Buyer From

| Location | Anywhere in India |

Mini Bay (mini tramp oil separator)

Filters23 India’s mini tramp oil separator is a compact and portable version of a tramp oil separator designed for smaller-scale applications or where space constraints are a concern. These devices are typically used in machine shops, small manufacturing facilities, or laboratory settings where there is a need to remove tramp oils from coolant or other liquids but without the space or volume requirements of larger industrial systems.

Here are some key features and considerations related to mini tramp oil separators:

Compact Size: Mini tramp oil separators are smaller in size compared to their industrial counterparts. They are designed to be more portable and fit into tight spaces, making them suitable for smaller workshops or laboratories.

Lower Capacity: These separators have a lower processing capacity compared to larger systems. They are ideal for situations where the volume of tramp oil to be removed is relatively small.

Simplicity: Mini tramp oil separators are often simple in design and easy to operate. They may use mechanisms such as belt skimmers, disk skimmers, or coalescing plates to remove tramp oil from the liquid.

Portable: Due to their compact size, mini tramp oil separators can be moved easily from one machine to another or from one location to another within a facility.

Manual or Semi-Automatic Operation: Depending on the specific model, mini tramp oil separators may offer manual or semi-automatic operation. Some may require periodic monitoring and manual adjustment, while others have automated features for tramp oil removal.

Maintenance: Like larger tramp oil separators, mini versions require regular maintenance to clean or dispose of the collected tramp oil. Maintenance intervals are typically shorter due to the smaller capacity.

Affordability: Mini tramp oil separators are often more affordable than larger industrial models, making them a cost-effective choice for smaller operations with limited budgets.

Applications: These separators are suitable for various applications, including small machining operations, benchtop lathes, 3D printing machines, and other equipment that uses coolants or cutting fluids.

When selecting a mini tramp oil separator, consider factors such as the volume of tramp oil generated, the type of coolant or liquid involved, the available space, and the level of automation desired. It's important to choose a separator that matches the specific needs of your application to ensure efficient tramp oil removal and maintenance of the liquid's quality.

| Business Type | Manufacturer |

| Condition | New |

| Operating Type | Automatic |

| Certification | ISO 9001:2008 |

| Type | Oil Removal Filter,FRYER OIL FILTER MACHINE |

| Country of Origin | India |

| Warranty | 1 Year |

| Brand Name | SHUBH LAXMI MACHINE TOOLS |

| Port | Sanand |

| Payment Terms | L/C, D/A |

| Delivery Time | 1-2 week |

Preferred Buyer From

| Location | Anywhere in India |

Fryer Oil Filter Machine

Filters23 India fryer oil filter machine, also known as a deep fryer oil filtration system, is a piece of equipment used in commercial kitchens, particularly in restaurants and foodservice establishments, to extend the lifespan of cooking oil used in deep fryers. These machines are designed to filter and clean frying oil, removing impurities, food particles, and contaminants to maintain the quality of the oil, reduce waste, and improve the taste and texture of fried foods. Here's how a fryer oil filter machine typically works and its key features:

How a Fryer Oil Filter Machine Works:

1. Filtration System: The machine is equipped with a filtration system that can include various components like a filter pump, filter housing, filter media (usually a disposable or reusable filter paper), and sometimes a separate holding tank for the used oil.

2. Hot Oil Handling: Fryer oil filter machines are designed to handle hot oil. They can be used while the oil is still hot, allowing for continuous frying operations.

3. Filtering Process: The oil from the deep fryer is pumped or drained into the filtration system, where it passes through the filter media. The filter media captures impurities, food particles, and other contaminants present in the oil.

4. Cleaned Oil Return: The filtered and cleaned oil is then pumped or returned to the fryer for reuse. This process improves the quality and clarity of the oil, resulting in better-tasting and more visually appealing fried foods.

5. Waste Collection: Any solid debris or contaminants captured by the filter media are typically collected in a waste container for easy disposal.

Key Features of Fryer Oil Filter Machines:

1. Various Sizes: Fryer oil filter machines come in various sizes and capacities to suit the needs of different commercial kitchens, from small restaurants to large food production facilities.

2. Portability: Many models are designed to be portable, allowing easy movement between fryers and making them suitable for use with multiple fryers.

3. Quick Filtration: These machines are designed for quick and efficient filtration, minimizing downtime during the cooking process.

4. Temperature Control: They can handle hot oil, often allowing for continuous filtering without the need to cool down the oil.

5. User-Friendly Controls: Most machines have user-friendly controls for easy operation.

6. Safety Features: They may include safety features to prevent spills and accidents, such as splash guards or locking mechanisms.

7. Extended Oil Life: Regular use of a fryer oil filter machine can significantly extend the lifespan of frying oil, reducing the frequency of oil changes and associated costs.

8. Improved Food Quality: Cleaner oil results in better-tasting and more visually appealing fried foods.

Fryer oil filter machines are essential in commercial kitchens where deep frying is a common cooking method. They help maintain the quality of cooking oil, reduce waste, and improve the consistency and taste of fried foods. The choice of a specific machine depends on the size of the fryer, the volume of frying done, and the filtration needs of the kitchen. Properly maintained oil can lead to cost savings and higher customer satisfaction.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Type | Hydraulic Oil Filters, Honing Oil Filter |

| Certification | CE Certified, ISO 9001:2008 |

| Application | Industrial Use, Honing Oil Filtration |

| Weight | 100-200gm, 300-400gm |

| Color | Black |

| Feature | Light Weight |

| Condition | New |

| Structure | Honing Oil |

| Warranty | 1year |

| Size | 3 X 3 X 1.5 Feet |

| Brand Name | SHUBH LAXMI |

| Production Capacity | 03 |

| Usage | Filter For Honing Oil |

| Name | Honing Oil Filter |

Preferred Buyer From

| Location | Anywhere in India |

we manufacturing oil filter which Oil Regeneration System is particularly suitable to regenerate used internal-combustion engine oil including diesel engine oil, gasoline engine oil and used hydraulic oil, other used machinery lubrication oil. This purifier can remove the tiny impurity dispersed in oil such as carbon Particles and deep oxides, as well as bad substance such as colloid and bitumen. Thus, the clarity of oil is recovered, engine oil quality improved, performance of engine restored, abrasion reduced, these would ensure correct operation of lubricant system of a engine and extend the life time of engine oil and engine as well. This kind of purifier is applicable to purification of various mixtures of used engine oil, diesel engine oil, car oil, motor oil and other industrial oil. We also manufacturing oil skimmers, coolant magnetic separators, paper band filterers.

Oil Filter Use And Maintenance

- In Order To Guarantee The Normal Work, Fine Filter Can Be Open To Vent Air Filter Canister.

- Oil Filter Vehicle Use After Period Of Time, For Crude Oil Filter Clogging Caused By Noise Increases, Should Be Timely Cleaning Crude Filter.

- Fine Filter Used After Period Of Time

- Low Maintenance And Replacement Express.

- Low Operation Cost.

- High Regeneration Rate.

- Automatic Reverse-washing System Will Extend The Lifetime Of Filters And Improve The Performance Of The Filters.

Application :

- Fine filter for hydraulic systems, fuel systems, lubricating system and the pressure of hydraulic oil system for infusion or regular filtering.

- For dirty oil also has a certain economic effect, is the ideal energy saving equipment.

| Type | Lube Oil Filters |

| Application | Compressor |

| Weight | 200-300gm |

| Color | Black |

| Feature | Perfect Filtration |

| Size | 3 X 3 X 5 Feet |

| Brand Name | SHUBHLAXMI |

| Name | Oil Filter trolly |

| Product Code | SMT-OT |

| Port | nahavasiva |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram, Other |

| Delivery Time | 15 days |

| Packaging Details | Export Type |

Preferred Buyer From

| Location | Anywhere in India |

Lube Oil Filter Trolly ( Universal )

25 L.P.M to 200 L.P.M

05 Micron to 25 Microns

Price : INR 65000 - 150000 -per- Piece(s)

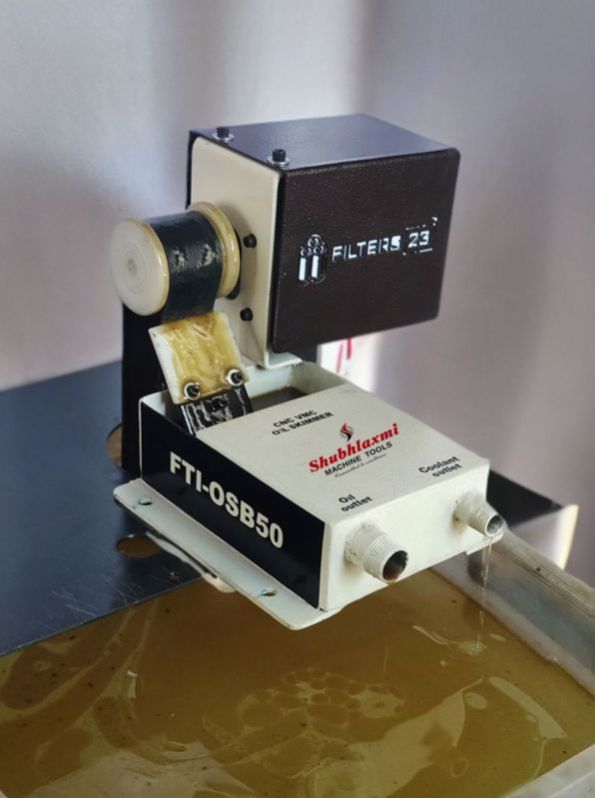

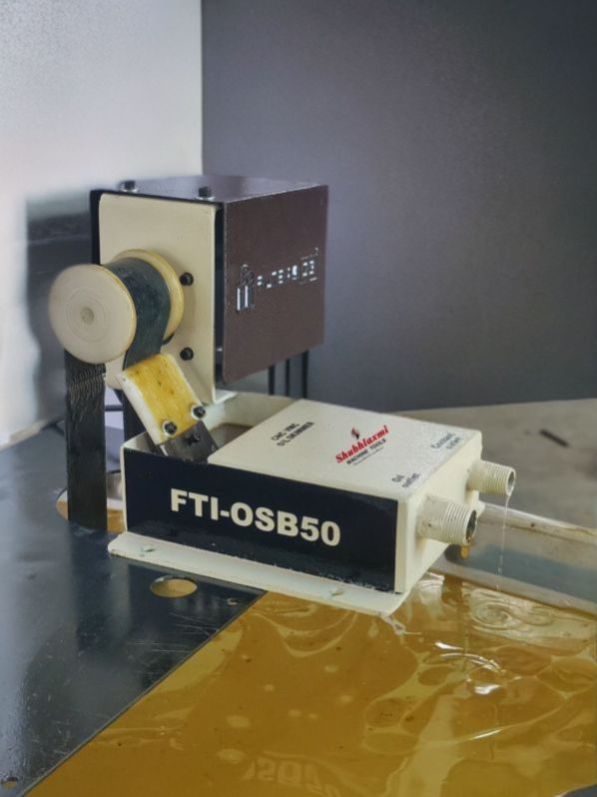

| Business Type | Exporter, Supplier |

| Brand Name | SHUBH LAXMI MACHINE TOOLS,SHUBHLAXMI MACHINE TOOLS |

| Finishing | Polished |

| Application | industrial OIL Skimmer |

| Size | as per need |

| Certification | iso |

| Type | Oil Skimmer,MINI OIL SKIMMER |

| Function | oil - water separation |

| Country of Origin | India,India |

| Warranty | 1 YEAR |

| Make | FILTERS23 INDIA PVT LTD |

| Port | Sanand |

| Delivery Time | 2-3 Weeks |

| Packaging Details | WOODEN BOX |

Preferred Buyer From

| Location | Anywhere in India |

Belt type oil skimmer is a mechanical device used for removing oil, grease, and other hydrophobic (water-repellent) liquids from the surface of water or other liquids. These skimmers are often employed in industrial and environmental applications to effectively separate and collect oil and grease contaminants from water bodies, process tanks, or other liquid surfaces. Here's how a belt type oil skimmer typically works and some key features:

Working Principle:

1. Endless Belt: A belt type oil skimmer consists of an endless loop of belt or a similar material. The belt is typically made of materials that repel water but attract oil, such as oleophilic (oil-attracting) materials.

2. Deployment: The skimmer deploys the belt into the liquid to be skimmed. The belt floats on the surface of the liquid, and a portion of it is submerged.

3. Surface Contact: As the belt travels along the liquid's surface, it comes into contact with the oil or grease on the surface. Due to its oil-attracting properties, the belt adheres to the oil, and the oil sticks to the belt's surface.

4. Oil Removal: The belt continues to move, carrying the adhered oil away from the liquid's surface. As it moves, the belt passes through a scraper or wiper mechanism that removes the oil from the belt's surface.

5. Collection: The collected oil is typically directed into a separate collection container or storage tank. The collected oil can then be periodically removed for disposal or recycling.

Key Features:

· Adjustable Speed: Many belt type oil skimmers feature adjustable speed controls, allowing operators to regulate the skimming rate based on the application's specific requirements and the volume of oil to be removed.

· Self-Adjusting: These skimmers are designed to automatically adjust to changes in the liquid level, ensuring efficient oil removal even if the liquid level fluctuates.

· Efficiency: Belt type oil skimmers are known for their high efficiency in removing oil and grease from water or other liquids. They can effectively remove both thin sheens of oil and thicker layers of oil.

· Low Maintenance: They typically require minimal maintenance, with routine cleaning and occasional replacement of wear parts being the primary maintenance tasks.

· Versatility: Belt type oil skimmers can be used in a wide range of environments, including industrial wastewater treatment, oil spill response, coolant recycling, and other applications where oil-water separation is necessary.

· Compact Design: Their compact and portable design makes them suitable for various settings and locations.

· Environmental Benefits: By removing oil and grease from water bodies, belt type oil skimmers help protect the environment by preventing the contamination of natural water sources.

Belt type oil skimmers are valuable tools for industries dealing with oily wastewater or encountering oil contamination problems. Their efficient and reliable operation contributes to cleaner and more environmentally friendly water management by effectively separating and collecting oil and grease contaminants.

Top of Form

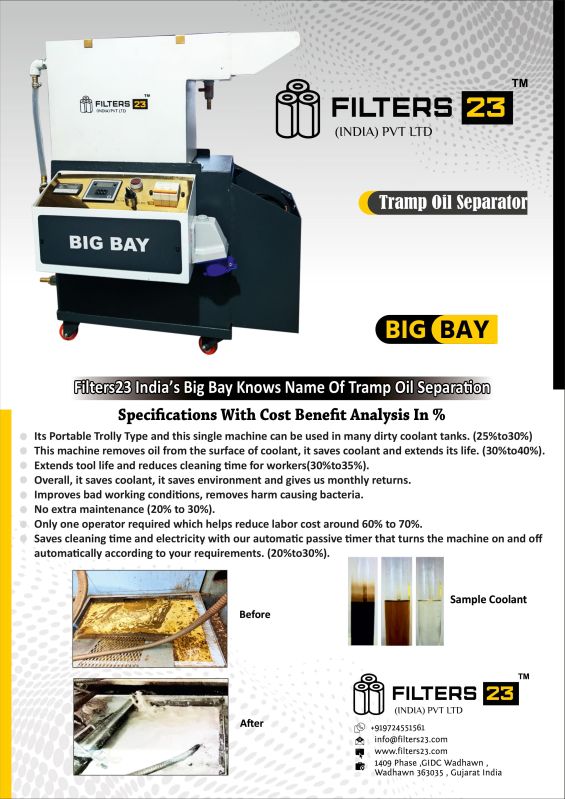

| Business Type | Manufacturer, Exporter |

| Usage/Application | OIL SEPARATOR |

| Finishing | Polished |

| Driven Type | Mechanical |

| Condition | New |

| Certification | ISO 9001:2008 Certified |

| Type | Oil Separator,TRAMP OIL SEPARATOR |

| Warranty | 1 Year |

| Country of Origin | India |

| Brand Name | SHUBH LAXMI MACHINE TOOLS |

| Payment Terms | L/C, D/A |

Preferred Buyer From

| Location | Anywhere in India |

Big Bay (tramp oil separator)

Filters23 India Pvt Ltd `s tramp oil separator, also known as an oil skimmer or oil separator, is a device used in industrial settings to remove unwanted oils, such as tramp oil, from coolant or wastewater. Tramp oil is oil that contaminates machine coolant, typically in metalworking or machining processes. It can come from various sources, including leaking hydraulic systems, lubricants, or residues from machining operations. Removing tramp oil is essential to maintain the quality and effectiveness of coolants and prevent issues like bacterial growth, reduced tool life, and poor surface finish in machining operations.

Here's how a tramp oil separator typically works:

Skimming Mechanism: Tramp oil separators are equipped with a skimming mechanism that comes into contact with the contaminated liquid. The skimming mechanism is designed to be selective, picking up and removing the floating tramp oil while leaving the coolant or wastewater behind.

Floating Oil Collection: As the skimming mechanism operates, it collects the tramp oil that naturally floats on the surface of the liquid. This oil can be in the form of a thin film or droplets.

Separation: Once collected, the tramp oil is separated from the liquid coolant or wastewater. This separation can occur through various means, depending on the design of the tramp oil separator. Common separation methods include gravity separation, coalescence, or the use of special materials that repel water but attract oil.

Oil Collection and Disposal: The separated tramp oil is typically directed into a collection container or reservoir for later disposal or recycling. Some tramp oil separators can automatically pump the collected oil to a separate storage tank.

Cleaned Liquid: The cleaned coolant or wastewater, now free of tramp oil, can be returned to the machining process or discharged as needed.

Key features and benefits of tramp oil separators include:

Improved Coolant Quality: By removing tramp oil, these separators help maintain the integrity of coolant, which is critical for machining processes' performance and tool life.

Reduced Environmental Impact: Proper disposal or recycling of the collected tramp oil minimizes environmental contamination.

Cost Savings: Longer coolant life and reduced tool wear translate into cost savings for maintenance and replacement.

Ease of Maintenance: Tramp oil separators are generally easy to maintain, with minimal downtime for cleaning and servicing.

Tramp oil separators come in various sizes and configurations to suit different industrial applications and coolant systems. The choice of a specific tramp oil separator depends on factors such as the volume of coolant, type of contaminants, and the desired level of automation for oil removal.